- Mob:0086-152-52900921 (WhatsApp)

- Email:info@toplasmachine.com

- Skype:tonyshi1028

The capacity 1000~

Comparing with PET washing recycling plant with capacity lower

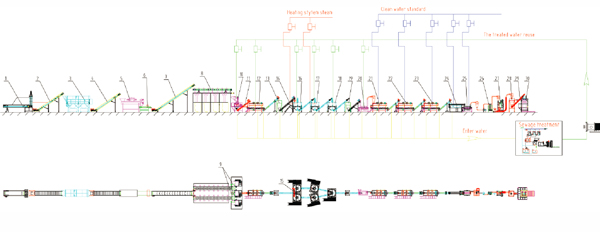

This line is mainly used to wash and recycle used PET bottles, mainly are from the drinking bottles. Such as the coke cola bottles, portable bottles. The colors of the bottles mainly have 3 types. The transported bottles, green bottles and blue bottles. As a recycling washing machinery line for the PET bottles, the main function of the plant is separating the labels from the bottles, removing the caps and washing the PET flakes cleaning.

Belt conveyer→mechanical label separator→manual sorting→metal detector→belt conveyer→wet crusher→screw conveyer→floating washer→screw conveyer→hot washer→screw conveyer→high speed friction washer→screw conveyer→floating washer→screw conveyer→vertical dewatering machine→drying system→zigzag label separator→storage silo---operating panel

Detailed parameters:

|

No. |

Name |

Motor Power |

Dimension |

Weight |

Necessity |

|

1 |

Belt conveyer |

1.5~2.2kw |

4000*700* |

|

Necessary |

|

2 |

Mechanical label separator |

18.5~22kw |

3200*1200* |

|

Necessary |

|

3 |

Manual sorting |

1.5~3.7kw |

6000*1000* |

|

Optional |

|

4 |

Metal detector |

0.4kw |

2000*1300* |

|

Optional |

|

5 |

Belt conveyer |

1.5~2.2kw |

4000*700* |

|

Necessary |

|

6 |

Wet crusher |

22~90kw |

1700*1600* |

|

Necessary |

|

7 |

Screw conveyer |

2.2~5.5kw |

3300*450* |

|

Necessary |

|

8 |

Cold rinsing washer |

3~5.5kw |

5500*1900* |

|

|

|

9 |

Screw conveyer |

2.2~5.5kw |

3300*450* |

|

Necessary |

|

10 |

Hot washer |

3~7.5kw |

1800*1800* |

|

Necessary |

|

11 |

Screw conveyer |

2.2~5.5kw |

3300*450* |

|

Necessary |

|

12 |

High speed friction washer |

22kw~37kw |

3000*900* |

|

Optional |

|

13 |

Screw conveyer |

2.2~5.5kw |

3300*450* |

|

Necessary |

|

14 |

Cold rinsing washer |

3~5.5kw |

5500*1900* |

|

|

|

15 |

Screw conveyer |

2.2~3.7kw |

3300*450* |

|

Necessary |

|

16 |

Vertical dewatering machine |

45~55kw/ |

1800*1800* |

|

Alternative |

|

17 |

Drying system |

22kw~30kw |

3000*2200* |

|

Optional |

|

18 |

Air label separator |

3kw~7.5kw |

1800*1000*3600 |

|

Optional |

|

19 |

Storage silo |

--- |

1600*1600* |

|

Necessary |

|

20 |

Electric panel |

Customized |

3000*600* |

|

Necessary |

Features and advantages of our recycling plant:

Safety: All our machines are made according to the CE standard. All rotating parts with safe fence or cover in case of any men body damaged. The maintenance opening parts are equipped with limited switch. All lines are quipped with emergency switch.

Material: All parts contacted with material are made of stainless steel SUS304 with thickness 3~

Long-life running: All steel parts are treated with anticorrosion, all stainless steel are SUS 304 with acid washing treatment.

Designing: All plants designed base on the real situation of customers’ material and our many years experience manufacturing the machines.

Energy saving: With reasonable designing to the structure of the plant, it can not only wash the material clean but also can help the custom to save power consumption which means to help customer create more profit.

360°services:

Customer requirements →Scheme designed →confirmed by customers →manufacturing →trial running in our factory →confirmed by customers →shipped → engineer available

Tag: PET bottle washing line PE PP film washing line Plastic recycling machine