- Mob:0086-152-52900921 (WhatsApp)

- Email:info@toplasmachine.com

- Skype:tonyshi1028

The main theory of the plastic granulating recycling machinery is by heating the extruder to melting the plastic to be soft. The soft plastic material go through the filter of the plastic granulating recycling machinery, then the dirty will be separated out.

After the filter of the plastic granulating recycling plant, the soft material will come out from the mould of the plastic granulating recycling plant. For the recycling machinery mould, there are many holes. The material comes out by noodle type. The noodle type material will goes into the water for cooling down. After cooling, the noodle material will become hard and can be cut into small granules by cutter. The size of the pellets can be controlled by adjusting the speed of the cutter.

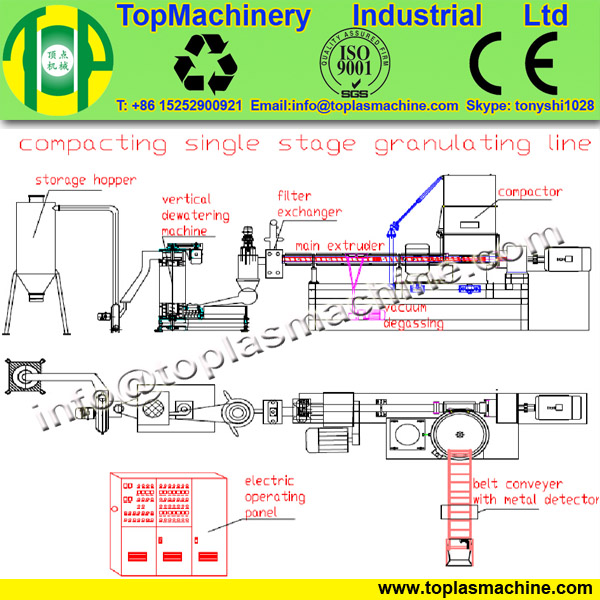

The feeding way of the plastic granulating recycling plant, for rigid material, it is easy. But the soft material, it is hard to feed into the extruder. So for the soft material, there are usually compacting feeding way, force feeder feeding way and side feeder feeding way.

Because the characters of different plastic are different, the temperature of the plastic granulating recycling plant settled is also different.

The plastic granulating recycling plant, some needs double stages. Some needs single stages depending on the different material and customers’ requirements.

The plastic granulating recycling plant, some noodle type, some die face type. Also it depends on the material and customers’ requirements.

Screw conveyer/belt conveyer→main extruder→sub-extruder→water cooling tank→force dryer→cutter→wind transition system→→storage silo--- electric panel

Models of PE PP film compactor granulating machine line

|

Diameter of screw |

PE capacity |

PP capacity |

|

|

Φ |

150 |

100 |

|

|

TCSJ-85/85 |

Φ85/ |

150 |

100 |

|

Φ |

280 |

250 |

|

|

TCSJ-100/100 |

Φ100/ |

280 |

250 |

|

Φ |

480 |

400 |

|

|

TCSJ-130/130 |

Φ130/ |

480 |

400 |

|

TCDJ-160 |

Φ |

650 |

600 |

|

TCSJ-160/160 |

Φ160/ |

650 |

600 |

|

TCDJ-180 |

Φ |

800 |

750 |

|

TCSJ-180/180 |

Φ180/ |

800 |

750 |

|

Feeding way of plastic pelletizing recycling plant: Special designed force feeder, side feeder and compactor can push the material into the extruder high efficiently. Guarantee getting good capacity of the machine. |

|

Gear reducer of plastic pelletizing recycling plant: The high torque, hard-surface gear reducer with water cooling circulation system ensures the line running steady, silent, and long life. |

|

Barrel and screw of plastic pelletizing recycling plant: The special material (38CrMoA |

|

Degassing of plastic pelletizing recycling plant: Special design for the venting can discharge the moisture and waste air efficiently which ensure the finally plastic granules are with smooth surface, no water, no bubble, and good quality. |

|

Hydraulic filter of plastic pelletizing recycling plant: Double position hydraulic filter works swift and easy to operate. Copper ring prevents the material leakage. |

|

Cutting way of plastic pelletizing recycling plant: Two type cutting way, the noodle type and water ring type makes the customer freely to choose. |

|

Special designed die of plastic pelletizing recycling plant: All die holes size are special designed due to the material characters and our rich experience to make machines. |

|

Cooling way of plastic pelletizing recycling plant: Most of the materials are cooled by water. Some like PVC are cooled by wind. |

|

Cutting way of plastic pelletizing recycling plant: pineapple cutter is for the noodle cutting way, and die face cutter for the water ring cutting way. |

|

Package of the final products of plastic pelletizing recycling plant: Final products granules will be blowing into silo, which will be packaged by manual or packaging scale machine |

|

Electric parts of plastic pelletizing recycling plant: Siemens, Schneider, |

Compactor feeder barrel of granulating line

360°services:

Customer requirements →Scheme designed →confirmed by customers →manufacturing →trial running in our factory →confirmed by customers →shipped → engineer available overseas→ whole life after sales services

Here is a brief and general introduction to our machines, if you want to know more details, please contact us with no hesitation. We will offer professional and formal information to you.

Tag: PE PP film granulating line PE PP film washing line Waste plastic recycling machine