- Mob:0086-152-52900921 (WhatsApp)

- Email:info@toplasmachine.com

- Skype:tonyshi1028

500kg/h PE PP woven bags washing recycling machine| jumbo bags crushing washing recycling line is usually a medium capacity for PE HDPE LDPE LLDPE film, package film, drinking water bags, shopping bags and PP woven bags, cement bags, jumbo bags crushing washing recycling plant. It is a very efficient washing recycling line for the soft Polyethylene and Polypropylene material.

The main processes of the washing recycling plant include granulator parts, floating washing parts, dewatering and drying parts final material collecting parts and the electric operating panel for all the system. By granulating, the dirty plastic films and bags, such as the farm film, plastic film from the city or earth waste, is granulator into small pieces. The granulator is wet type. It granulates with water. Actually it should be the first step to wash the dirty material when granulating. It is like a kind of pre-washer. The granulated small pieces film and woven bags goes into the floating washing tank. In the floating washing tank, the dirty materials are immersed in the water. Most of the dirties will sink down to the bottom of the floating rinsing tank, such as the sand, earth, stones, glass, etc… On the other point, it also can soften the strong dirties on the surface of materials, like the glue and oil on the film or woven bags surface. After the floating washing tank, usually a high speed friction washer will be arranged. Because the strong dirties on the surface of the agriculture film and bags have been already softened, then it is very easily to be removed by high speed friction washer. Next the washing parts are the dewatering and drying parts. Usually for PE PP farm film and woven bags or jumbo bags flakes dewatering, there are usually two models. One is the centrifugal dehydrator common seen by us, which removes the water by high speed rotating to make centrifugal power to remove the water on the surface of the material flakes. The other one is a kind of dewatering model which is more and more popular recently years. It is the squeezer. Usually the dewatering parts will be linked with the drying parts to make sure the final film or bags flakes water level lower than 5%, which is enough to be taken directly to the pelletizing plant to make pellets.

The entire structure of this HDPE PE PP LDPE LLDPE soft mateiral is designed based on our many years experience to manufacture the recycling machines. Simple structure, compact component, low energy consumption, safe and easy operating, simple maintenance. All these good points are to help the customer to get good profit.

The parts of machines contacted with material are made of stainless steel SUS 304 with thickness from 3mm to 6mm. It can ensure the recycling plant running for a long time. Normally it can run 6~7 years. With well maintenance, it can run 8~10 years.

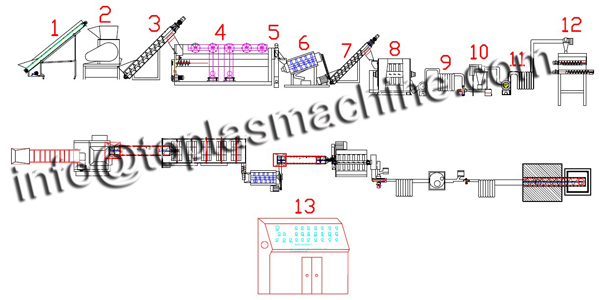

Technical flows:

belt conveyer→wet granulator→screw conveyer/friction washer→floating rinsing washer→screw conveyer→high speed friction washer→screw conveyer→horizontal dewatering machine/ squeezer→drying system 1→transition hopper→drying system 2→storage silo--- electric panel

Detailed parameters:

|

No. |

Name |

Motor Power |

Dimension |

Weight |

Necessity |

|

1 |

Belt conveyer |

1.5~2.2kw |

4000*800* |

|

Necessary |

|

2 |

Wet crusher |

45~75kw |

2000*2200* |

|

Necessary |

|

3 |

Screw conveyer/ friction washer |

3.7~7.5kw |

3300*450* |

|

Alternative |

|

4 |

Floating rinsing washer |

4.5~6.6kw |

6500*2000* |

|

|

|

5 |

Screw conveyer |

2.2~3.7kw |

3300*450* |

|

Necessary |

|

6 |

High speed friction washer |

22kw~37kw |

3200*1000* |

|

Optional |

|

7 |

Screw conveyer |

2.2~3.7kw |

3300*450* |

|

Optional |

|

8 |

Horizontal dewatering machine/ film squeezer |

55~75kw/ 55~75kw |

2000*2200* 2000*1100* |

|

Alternative |

|

9 |

Drying system 1 |

36kw~72kw |

3000*2200* |

|

Optional |

|

10 |

Transition hopper |

--- |

1200*1200* |

|

Optional |

|

11 |

Drying system 2 |

36kw~72kw |

3000*2200* |

|

Optional |

|

12 |

Storage silo |

--- |

1600*1600* |

|

Necessary |

|

13 |

Electric panel |

Customized |

3000*600* |

|

Necessary |

Safety: All our machines are made according to the CE standard. All rotating parts with safe fence or cover in case of any men body damaged. The maintenance opening parts are equipped with limited switch. All lines are quipped with emergency switch.

Material: All parts contacted with material are made of stainless steel SUS304 with thickness 3~

Long-life running: All steel parts are treated with anticorrosion, all stainless steel are SUS 304 with acid washing treatment.

Designing: All plants designed base on the real situation of customers’ material and our many years experience manufacturing the machines.

Energy saving: With reasonable designing to the structure of the plant, it can not only wash the material clean but also can help the custom to save power consumption which means to help customer create more profit.

360°services:

Customer requirements →Scheme designed →confirmed by clients →manufacturing →trial running in our factory →confirmed by clients →shipped → engineer available overseas→ whole life after sales services

Here is a brief and general introduction to our machines, if you want to know more details, please contact us with no hesitation. We will offer professional and formal information to you.

Tag: PE PP film washing line PE PP film granulating line PET bottle washing line

Features and advantages of our recycling plant: